|

OBJECTIVES Ob.1 Production, isolation and purification of various wt- and mutant PAL and PAM. ∑Wt-PAL from various mesophiles

and termophiles will be produced by fermentation.

The enzyme activity and stability will be tested and optimal condition for

highest reaction rate will be established. Cloning known and novel bacterial

useful PALís into the most proper hosts for larger scale productions. Ob2. Immobilization of PAL and

PAM, and whole cells hosting PAL/PAM production. We plan to develop robust

immobilization techniques with isolated enzymes as well as with whole cells

producing MIO-containing enzymes. The immobilization method can

basically determine the reusability and activity of enzymes,

moreover it can affect the substrate specificity of the biocatalysts. Several

immobilization methods including adsorption binding onto surfaces, entrapment

or cross-linking will be performed and compared their feasibility and

efficiency. Ob3. Development of biocatalytic procedures mediated by PAL/PAM The broad substrate tolerance of PAL

will be exploited further by using wild-type or mutant native or immobilized mesophile and extermophile

enzymes for the efficient production of both enantiomers of various aryl-alanines. Natural or engineered cells will be also

checked as potential biocatalysts. Batch and continuous flow processes will

be compared as efficiency. A continuous flow sequential procedure will be

developed for the simple and efficient production of unnatural

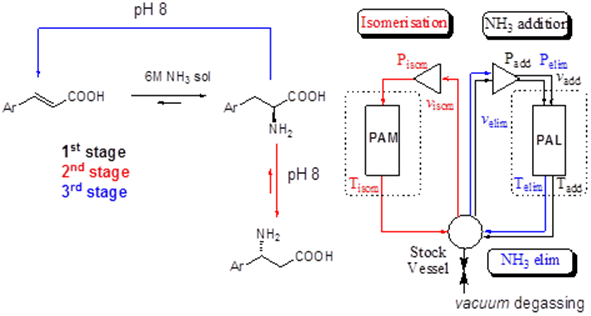

β-phenylalanine analogs using as starting material various aryl-cinnamates as shown. In the first stage PAL catalysed ammonia addition (6M NH3 water

solution) will provide L-arylalanines. After the

reaction will ceased the solution will be degassed and the pH will be

adjusted to 8. In the second stage the PAM catalysed

izomerization will provide the corresponding

β-arylalanine. Finally the unreacted L-arylalanie will be transformed into the starting arylacrylate.† |